Solutions for the food industry

Different works. Different Solutions

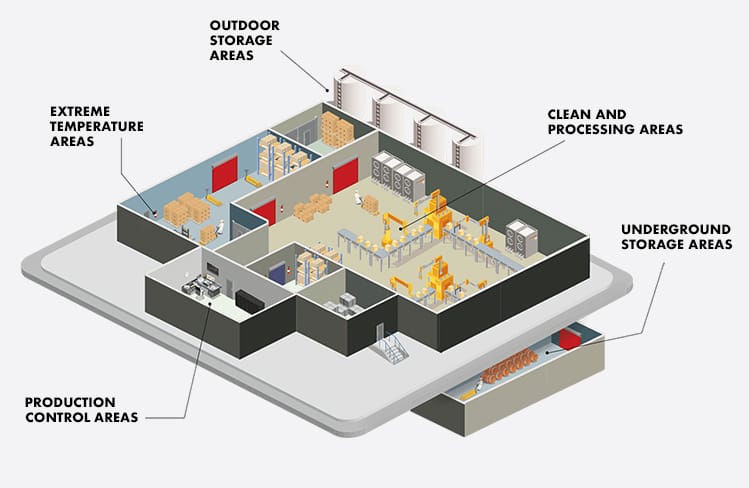

We understand as food industry the part of the industry that is in charge of the processes related to the food chain. The phases of transport, reception, storage, processing and conservation are included within the concept.

The raw materials of this industry consist mainly of products from plants (agriculture), animals (livestock) and fungal (relative to mushroom) origins.

Thanks to food science and technology, the progress of this industry has been increased. The increase in food production has been combined with a progressive effort in the surveillance and assurance of hygiene and food laws of the countries trying to regulate and unify the processes and the products.

Basor Electric has been able to interpret these new industry developments for a more professional offering to our clients. Basor offers the best solutions for the food sector with the highest quality and always meeting the most demanding standards.

Download

our

catalog

Download

Our solutions

Technical addendum

Norm: EN 1672-2:2005+A1:2009

This addendum specifies the common hygiene requirements for the machines and facilities used in the preparation and processing of food for human use and, where appropriate, consumption of animals to eliminate the risk of contagion, infection, disease or injury caused by these foods.

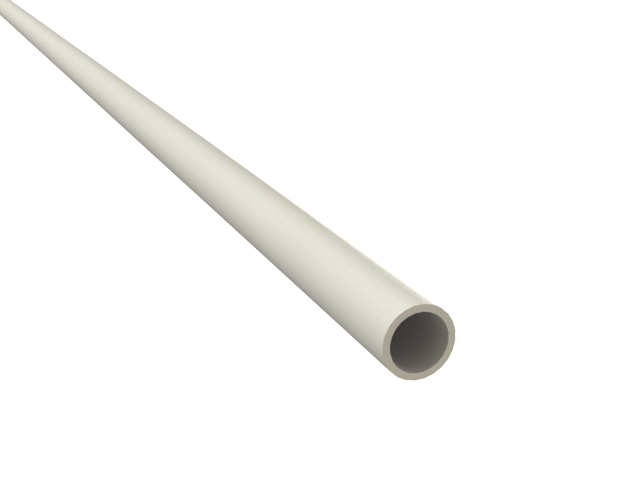

Raw materials in installed products

The surfaces of the materials shall be durable, cleanable and, when necessary, capable of being disinfected, without breaks, resistant to cracking, chipping, scaling or abrasion, avoiding the penetration of unwanted materials.

In addition to this, the materials will be:

- Corrosion resistant

- Non-toxic

- Non-absorbent

- It should not transfer odors, colors or stains

In non-food areas, materials should be made of corrosion resistant material or material that is treated (coated or painted) to be corrosion resistant, these surfaces should be cleanable as well.

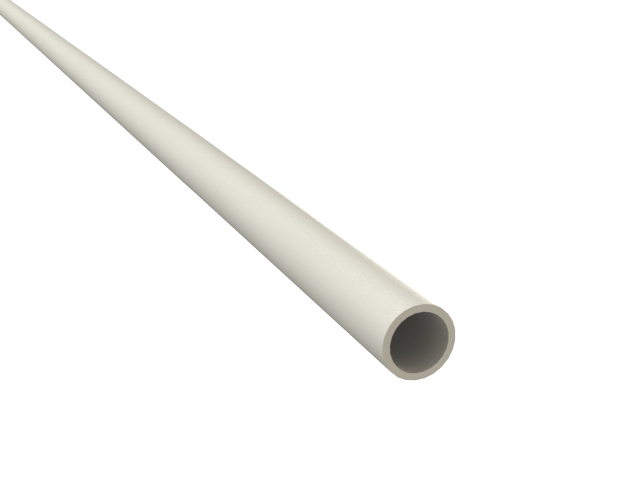

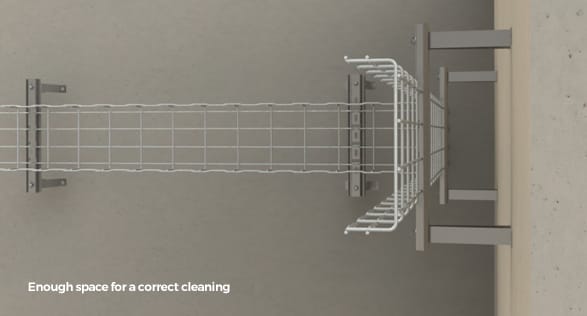

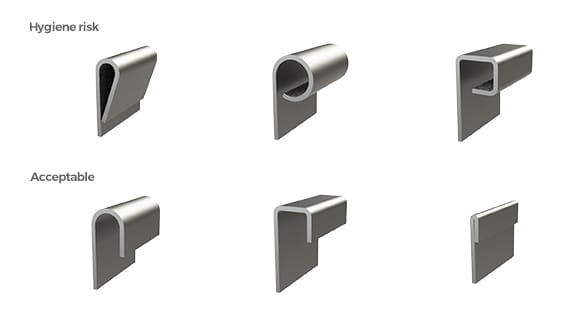

Cleaning

Surfaces must be finished so that no product particles are trapped in small indentations as it will be difficult to dislodge. Surfaces must be able to be cleaned and, when necessary, can be disinfected.

For this they must be smooth, continuous or sealed.

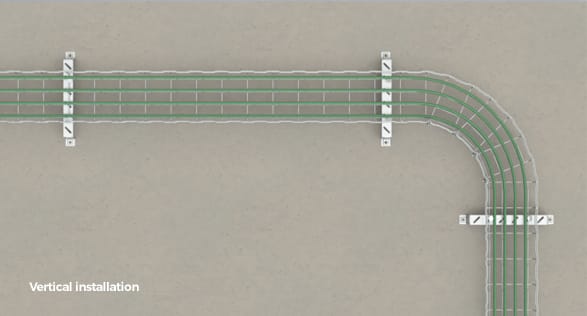

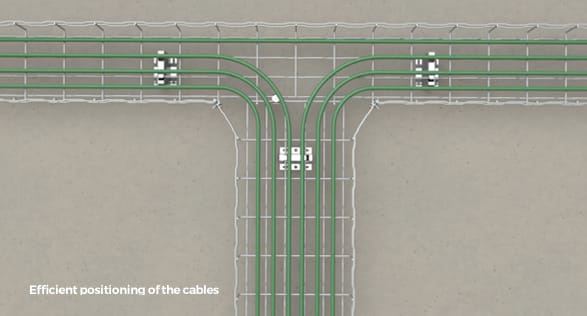

Instalation

A sanitary facility for a food factory must be designed to keep the number of microbes low. Pests, such as insects, rodents, and other animals, should be don´t be appear and should not find places where they can breed:

- Corrosion resistant

- Non-toxic

- Non-absorbent

- It should not transfer odors, colors or stains